1. Manual Powder Coating Machine and Oven Overview

A Manual Powder Coating Machine and Oven combo is a versatile system designed for small-scale powder coating applications. The machine includes a powder spray gun, electrostatic generator, and powder hopper, while the oven features an insulated chamber and heating elements. Together, they provide a complete solution for applying and curing powder coatings, ensuring durable, high-quality finishes.

2. Applications of Manual Powder Coating Machine and Oven

This system is ideal for small workshops, hobbyists, and repair shops. It is used to coat and cure parts like automotive components, bicycle frames, tools, and household items. The manual setup offers flexibility, making it suitable for custom projects and low-volume production.

3. Pricing of Manual Powder Coating Machine and Oven

The cost of a Manual Powder Coating Machine and Oven typically ranges from 3,000to15,000, depending on size and features. Factors influencing price include oven capacity, heating technology, and additional accessories. This system is an affordable option for small businesses and DIY enthusiasts.

4. Proper Usage of Manual Powder Coating Machine and Oven

Begin by cleaning and pre-treating the surface. Use the manual spray gun to apply powder evenly, maintaining a consistent distance. Transfer coated parts to the oven and cure at the recommended temperature (350°F–450°F). Monitor curing times and clean the spray gun regularly for optimal performance.

5. How to Choose the Right Manual Powder Coating Machine and Oven

Select a system based on part size, production volume, and workspace. Prioritize ovens with precise temperature control and efficient insulation. Ensure the spray gun offers adjustable settings for different materials. Look for safety certifications and user-friendly designs.

6. Safety Precautions for Manual Powder Coating Machine and Oven

Operators must wear protective gear, including respirators and heat-resistant gloves. Ensure proper ventilation to prevent fume buildup. Regularly inspect electrical components and grounding systems. Install fire-resistant flooring and emergency shut-off systems.

7. Design Efficiency of Manual Powder Coating Machine and Oven

This system is designed for compact workspaces, combining efficient powder application with precise curing. Insulated ovens reduce heat loss, while manual spray guns offer flexibility. The integrated design ensures consistent, high-quality finishes with minimal waste.

8. FAQs About Manual Powder Coating Machine and Oven

Q1: What temperature is ideal for curing in a manual powder coating oven?

A1: Most powders cure effectively between 350°F and 450°F, depending on material specifications.

Q2: Can this system handle large parts?

A2: Yes, with proper setup, it can accommodate large and irregularly shaped parts.

Q3: How do I maintain the manual powder coating machine?

A3: Clean the spray gun and filters regularly, and inspect hoses for leaks.

Q4: Is this system energy-efficient?

A4: Yes, insulated ovens and manual operation minimize energy consumption.

Q5: What safety features are essential?

A5: Look for automatic shut-off, temperature alarms, and proper ventilation systems.

This guide provides a comprehensive overview of manual powder coating machines and ovens, highlighting their applications, pricing, and safe operation. By selecting the right equipment and following best practices, users can achieve professional-quality finishes efficiently.

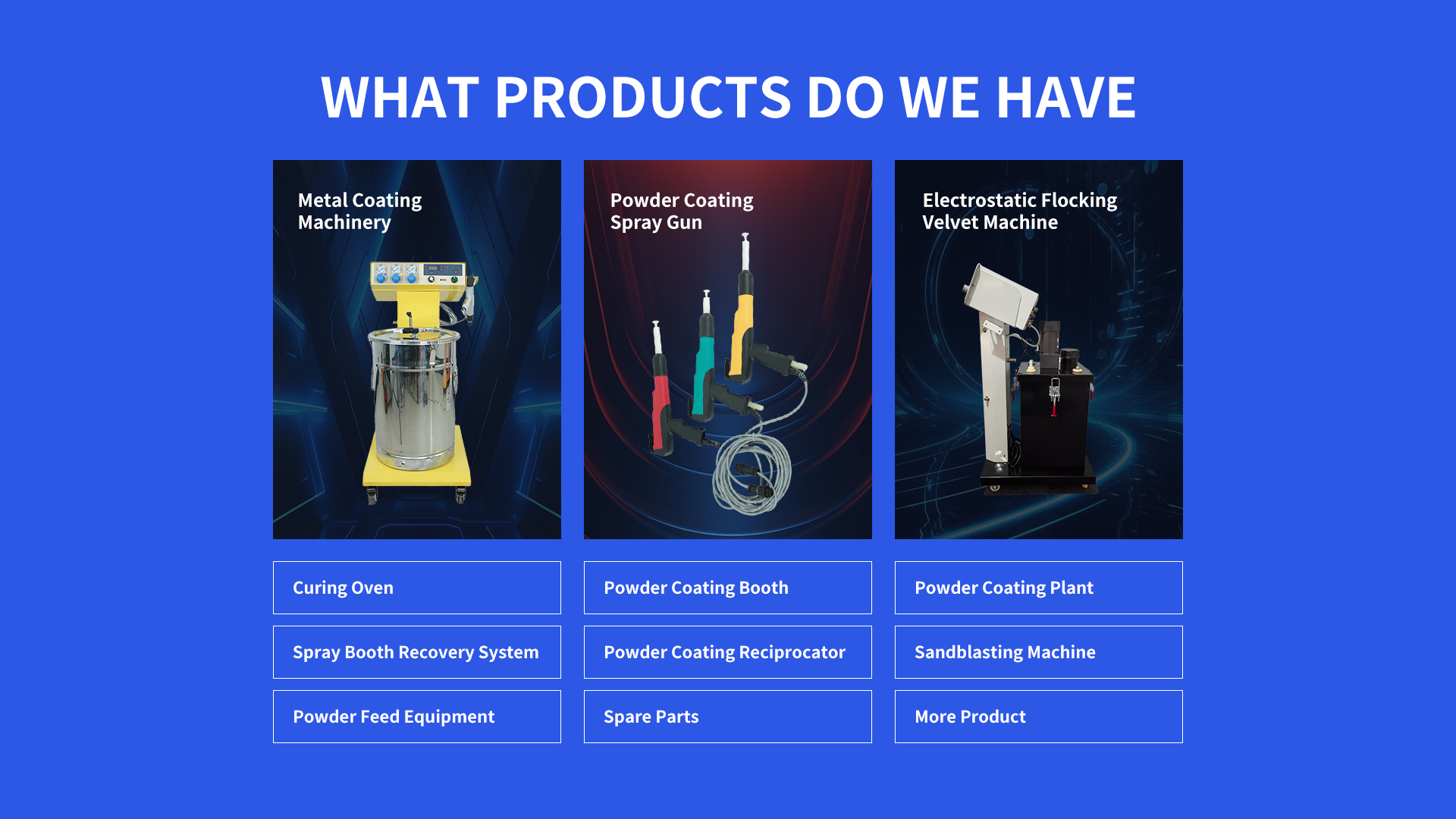

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com